ENGINEERING & RISK ASSESSMENT

Risk Assessment

Risk assessment isn’t just a compliance exercise — it’s a critical component of building consistent, high-reliability operations.

TintedSun provides practical, engineering-focused risk analysis tailored to your organization’s real manufacturing environment.

Drawing on two decades of hands-on experience in electronics manufacturing, Jason Davis helps OEM and EMS teams identify potential points of failure in design, sourcing, process flow, and execution. Our assessments look beyond procedure to uncover where risk truly lives — on the production floor, inside the BOM, or between departments.

We work with your teams to implement structured, actionable controls that improve visibility, reduce rework, and strengthen confidence in delivery performance. The goal isn’t just compliance — it’s building a process that works under real-world pressure.

Obsolescence Review

Component availability can change faster than most programs can adapt.

TintedSun helps OEM and EMS teams anticipate lifecycle risk early by reviewing BOMs and approved vendor lists for parts nearing end-of-life, allocation, or extended lead times.

Our reviews combine engineering, sourcing, and lifecycle data to pinpoint at-risk components before they threaten build continuity. We assess manufacturer stability, technology maturity, and cross-supply health to determine the best path forward—whether that’s identifying form-fit-function alternates, qualifying second sources, or refining your AVL to strengthen supply resilience.

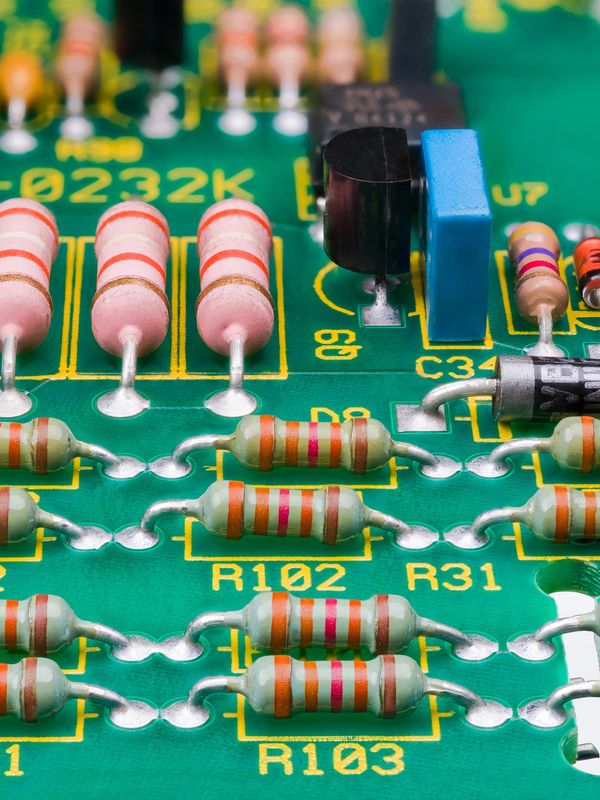

As legacy through-hole components continue to phase out in favor of surface-mount technologies, we help teams navigate transitions without costly redesigns—identifying compatible replacements, managing qualification, and aligning documentation to ensure continuity through the change.

This proactive approach integrates engineering insight with supply-chain awareness, helping you prevent redesigns, avoid line-down situations, and maintain production stability throughout a product’s lifecycle. The result is a build strategy that remains predictable, compliant, and cost-effective even as the component market evolves.

Process Improvement

Every operation hits points of friction — places where process, communication, or accountability break down.

TintedSun helps manufacturing organizations regain efficiency by identifying the root causes of lost productivity and margin erosion.

We take a collaborative, on-the-ground approach, working directly with your engineering, production, and purchasing teams to map workflows, eliminate redundancy, and restore control to critical processes. Whether the challenge involves quoting, NPI handoff, material planning, or production throughput, we help you remove friction and rebuild flow.

Jason’s background in engineering leadership and cross-functional operations ensures our recommendations are both realistic and implementable, not theoretical. Our focus is always on achieving sustainable, measurable improvement — helping you perform with predictability, precision, and confidence.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.